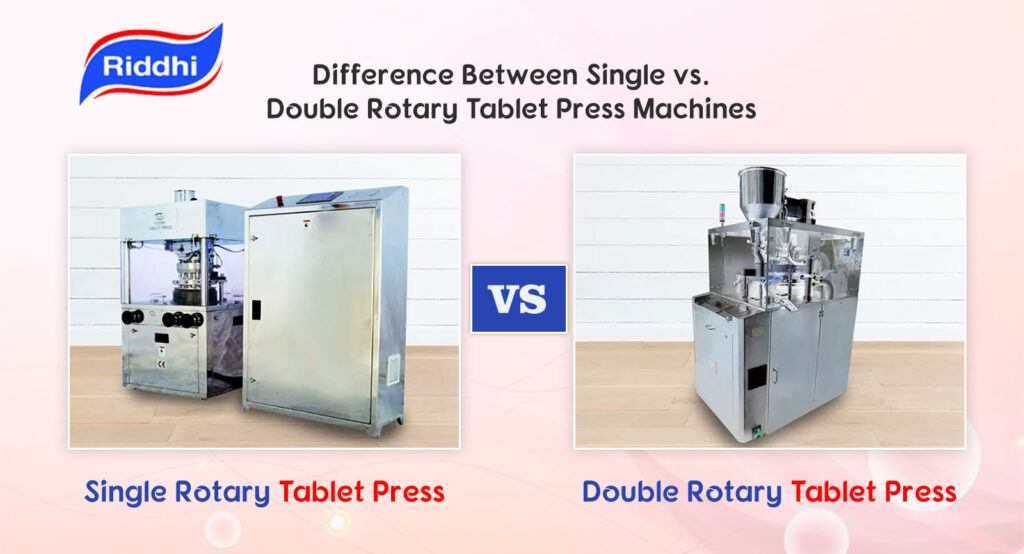

Difference Between Single vs. Double Rotary Tablet Press Machines

Rotary tablet press machines are used in pharmaceutical manufacturing to maximize their production efficiency and ensure product quality. Among the several variations available, single and double rotary tablet presses are two of the most popular. This blog post explains the difference between a double and single rotary tablet press machine.

Single Rotary Tablet Press vs. Double Rotary Tablet Press

Single Rotary Tablet Press

These presses are compatible with a range of materials and may manufacture tablets of various shapes and sizes. The rotational action of the press guarantees that the tablets are equally squeezed and have the same shape.

Single rotary presses are offered in manual and automated configurations. You can operate the manual press with a hand crank. And, an automatic press operates with an electric motor.

Double Rotary Tablet Press

The twin rotary tablet press consists of two rotating plates, each with its own set of dies. This tablet press is often utilized in big manufacturing runs. The primary advantage of a rotating tablet press is its ability to create huge volumes of tablets quickly and with minimal operator fatigue.

Tablet presses produce tablets in different forms, sizes, and weights. The only drawback of these presses is that they require specific tooling to build the correct tablet form and size. Tablet press tooling can be pricey, but it is usually worth the investment in high-volume manufacturing.

Working Process:

The operating mechanism for a single rotating tablet press is easy. Granular material is fed into the die chamber, and as it rotates, the top and lower punches compress it to produce a tablet. This sequential method enables accurate tablet production at each location.

The Double Rotary Tablet Press has two sets of compression stations that allow for simultaneous tablet creation with each turn. As the turret turns, tablets are made simultaneously at each station increasing the machine’s output capacity over single rotary tablet presses.

Changeover Time:

Single rotary tablet presses need a short changeover time between product runs. This enables the processing of numerous formulas and increases manufacturing flexibility.

Double rotary tablet presses require longer changeover times because of their dual-station architecture.

Capacity:

A single rotary tablet press has low output capacity as it depends upon only one compression station. The number of tablets produced on each rotation restricts the output rate.

Double Rotary Tablet Press uses double compression stations that operate concurrently and offer high output rates. This parallel processing capacity enables continuous and quick tablet production.

Cost:

A single rotary tablet press is cheaper than a double rotary press. This rotary press is an ideal choice for small businesses.

Double rotary tablet presses need a higher initial investment. However, these presses provide more output capacity and higher ROI for large-scale production.

Parting Words

Single rotary tablet presses are simple, small, and cost-effective. And, twin rotary presses provide increased production capacity and throughput. Riddhi Pharma offers rotary presses customized to your specific requirements.

Riddhi Pharma Machinery Ltd.

Riddhi Pharma Machinery Ltd. has expertise in manufacturing pharmaceutical machinery. We have 28 years of experience in providing high-quality machinery solutions.