- Home

- Encapsulation Machine

We have been able to provide top-quality Encapsulation Machines to our distinguished customers due to our extensive expertise and deep understanding of this sector. Encapsulation is the process of filling empty capsules with active pharmaceutical components. These are high-performance machines that feature the most recent worldwide design and are precision-built utilizing the best materials and cutting-edge production techniques. Aside from that, the machine’s functioning is fairly easy.

Gives you better results.

Our High Quality Product

These fillers are used for capsule filling in a range of pharmaceutical industries. They are available in a variety of shapes, designs, and production capacities to fulfill the ever-changing demands of the pharmaceutical sector.

It works by filling hard or soft gelatin capsules with various substances such as pellets, powder, liquid, or solution. To guarantee optimum client satisfaction, our logistics team ensures that these capsule fillers are delivered to the customer on time. In India, we are a prominent Encapsulation Machine suppliers.

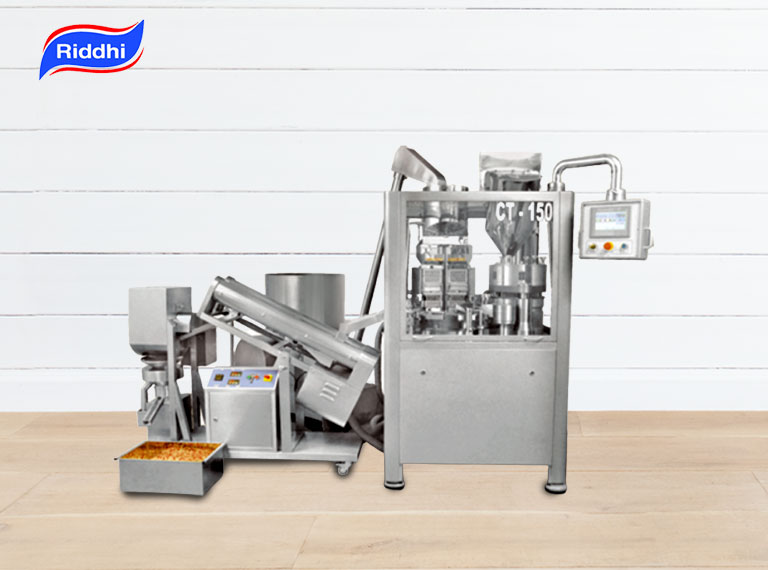

Automatic Capsule Filling Machine

The filling machine model RDCFM-150 is a fully automatic capsule filling and closing machine,suitable for filling powder/pellets in hard gelatine capsules. It adopts intermittent motion and multi-position tamping method to complete capsule orientation, separation, filling, closing and ejection etc.

With different size parts the machine is suitable for size 00, 0, 1, 2, 3 & 4 of empty capsules. The production speed can be controlled by means of a VFD variable frequency drive. The machine is designed in accordance with GMP standard. All product contact parts are made of SS 316 & machine covered by SS 304. Advantage of the machine is advanced design, study structure, precise dosing, and safe and reliable, high filling rate etc.

| RDCFM 150 – 1,50,000 capsules / hour |

| RDCFM – 90 – 90, 000 capsules / hour |

| RDCFM – 70 – 70, 000 capsules / hour |

| RDCFM – 40- 40, 000 capsules / hour |

| RDCFM – 25- 25, 000 capsules / hour |

| R. NO | PARTICULAR | RDCFM – 25 | RDCFM – 40 | RDCFM – 90 | RDCFM – 150 |

| No. | *Output / hr | 25,000 Capsules | 40,000 Capsules | 90,000 Capsules | 150,000 Capsules |

| UTILITIES | |||||

| 1 | Power Supply 3 Phase, 415V, 50Hz | 3 Phase, 1 Neutral, 1 Earthling | 3 Phase, 1 Neutral, 1 Earthling | 3 Phase, 1 Neutral, 1 Earthling | 3 Phase, 1 Neutral, 1 Earthling |

| 2 | Connected Load HP / Kw | 6/4 | 6/4 | 7.5 / 5.7 | 7.5 / 5.7 |

| 3 | Compressed Air | 4 CFM | 4 CFM | 4 CFM | 4 CFM |

Manual Or Hand Capsule Filling 300 Holes

The machine is manually operated with all non contact parts are made out of S.S. 304 quality except Harden & Lubricated parts, The machine is suitable for filling any one size of capsule, with all contact parts are made out of S.S 316 qty, 1 no. top plate, 3 Nos. loading plate, 1 no. powder tray made out of S.S 316 quality, with 1 no. nylon double head brush, 1 no. powder dispenser & 3 nos allenkeys.Size 0 and 1, 2 can be used in one machine. Size 3 and 4 can be used in one machine.

| STANDARD MODEL |

| All contact parts are made of stainless steel 304 quality |

| All other associated parts are hard chrome plated |

| The output ratio obtained is 60,000 to 65,000 as per 8 hour shift |

| Loading trays included |

From Size 00/0/1/2 you can do one machine with change parts, for size 3,4 you will have to do one other machine, for size 5 one machine, for size 000 a separate machine.

Output: 2 to 2.5 Lakh capsule per shift

Drive: ¼ HP, 3 phase motor, 1400 RPM

Dimension: 630 x 430 x 780 mm

Weight: 75 Kg.

Manual Capsule Filling Machine

This is most versatile Capsule Filing Machine suitable for all class of Pharmaceutical, Ayurvedic and R. & D. Laboratories. The equipment is simple to operate with NO weight variation and with negligible rejection.

The Stainless Steel body is fabricated out of S.S. 304 qlty. and all contact parts are made out of Stainless Steel 304 qlty. 8000 capsules per hour for capsule size:00 to 5 for 300-hole machine. Loading plates 3 Nos. and powder tray supplied with machine. From Size 00/0/1/2 you can do one machine with change parts, for size 3,4 you will have to do one other machine, for size 5 one machine, for size 000 a separate machine.

| Operation: Manual |

| Dimensions: 405mm x 300mm x 455mm |

| Weight:40 Kg |

Semi Automatic Capsule Filling Machine (Single Loader)

The semi automatic capsule filling machine is made out as per GMP standard suitable to fill powder, granules and pellets in empty capsule.The stand of body is made out of mild steel clad by S.S 304 quality. The covering of the body is made out of S.S 304 quality mate finish and the top covering is made out of S.S 316 quality mirror finish.

The hopper of the loader is fabricated and made out of S.S 304 quality the loader section is made out of brass & aluminum duly hard chrome plated & anodize with aluminium loading ring. The loader drive with the means of ½ H.P 3 phase electric motor.

The drug hopper is made out of S.S 316 quality with starrer and auger made out of S.S 316 fitted in drug hopper to fill the powder inside the empty capsule the movement of drug hopper is function with pneumatic cylinder the drug hopper drive with means of 1 H.P 3 phase electric motor and the filling table drive with means of ½ H.P gear motor 3 phase electric with variable speed drive.The closing section is operated with the means of pneumatic cylinder

| No of holes for Loading Ring | 360 | 480 | 540 | 600 |

| Output per hour | 16,000 | 22,000 | 25,000 | 27,000 approx. |

All the above output is depending on formulation and operator skill.The machine is available with single loader in [PLC] programmable logical control system with Automatic capsule closing system suitable for filling any one size ofcapsule with 2 set Aluminium loading ring, 2nos extra auger, pallet filling attachment & FRL 1.) 3 h.p motor, 440 volts,50 Hz, 1440 rpm, 500 mm [20”] of Hz at 1000 Lts/min (30 cmf)

Semi Automatic Capsule Filling Machine (Double Loader)

The semi automatic capsule filling machine is made out as per GMP standard suitable to fill powder, granules and pellets in empty capsule .The stand of body is made out of mild steel clad by S.S 304 quality The covering of the body is made out of S.S 304 quality mate finish and the top covering is made out of S.S 316 quality mirror finish.

The hopper of the loader is fabricated and made out of S.S 304 quality the loader section is made out of brass & aluminum duly hard chrome plated & anodize with aluminum loading ring. The loader drive with the means of ½ H.P 3 phase electric motor.

The drug hopper is made out of S.S 316 quality with starrer and auger made out of S.S 316 fitted in drug hopper to fill the powder inside the empty capsule the movement of drug hopper is function with pneumatic cylinder the drug hopper drive with means of 1 H.P 3 phase electric motor and the filling table drive with means of 1 H.P gear motor 3 phase electric with variable speed drive.The closing section is operated with the means of pneumatic cylinder.

| No of holes for Loading Ring | 360 | 480 | 540 | 600 |

| Output per hour | 21,000 | 26,000 | 32,000 | 35,000 app. |

Modifications to fit the needs of the clients!

Empty capsules are loaded onto the segment plate, capsules are opened, the powder is filled, un-separated capsules are ejected, capsules are closed, filled capsules are discharged, and the segment is cleaned. The completely enclosed construction keeps dust out of the moving parts.

Request A Quote

Quick Contacts

Please feel free to contact our friendly staff with any medical enquiry.

- Mob. No.: +91-9821018579/9969994187

- Location: Om shivam, Gr. Floor, 2, Tarun Bharat, Sahar Road, Andheri East, Mumbai -400099, India

- Mail: sales@riddhipharma.com